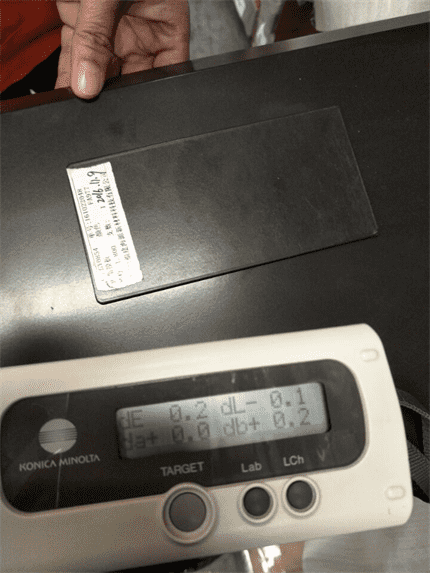

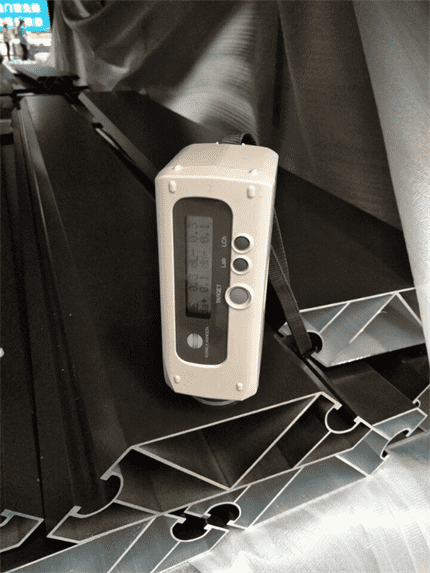

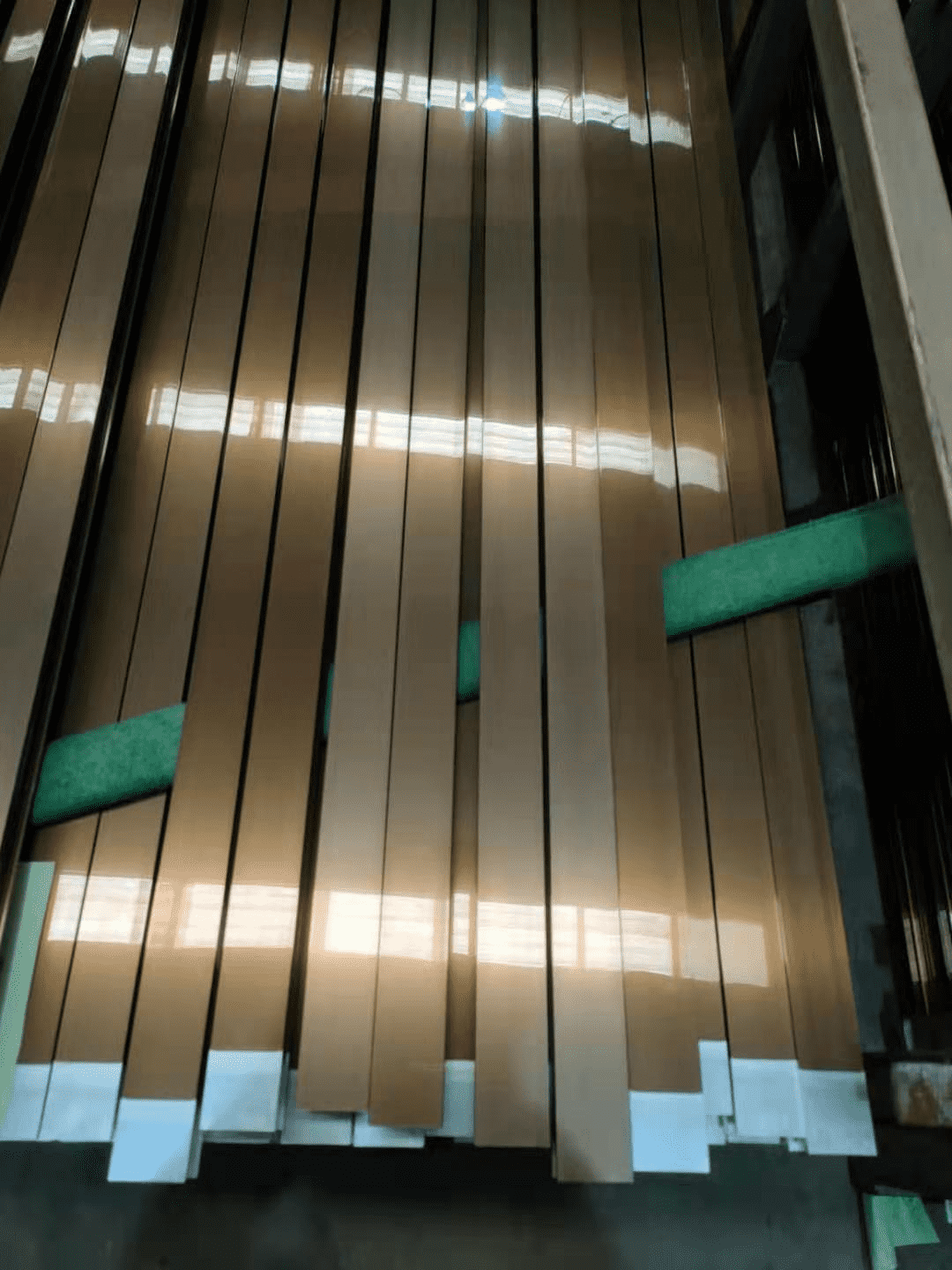

A lahani na aluminum canza launi kullum suna da wadannan yanayi: haske launi, launi bambanci, rini, farin tabo, fari, rini, launi gudun hijira, da dai sauransu Yadda za a warware wannan matsala don tabbatar da cewa bambancin launi na kowane tsari na samfurori ya kasance m kuma A cikin kewayon sabawa da bangarorin biyu suka tabbatar don biyan buƙatun mabukaci.Wannan yana buƙatar masana'antun samarwa don yin nazari da kiyaye yanayin yanayin yanayin launi na electrochemical na bayanan martaba.

Dalili da maganin launin haske da bambancin launi

1. The kauri na oxide fim ne m.Dalili mai yiwuwa shi ne cewa yawan zafin jiki da kuma maida hankali na anodic hadawan abu da iskar shaka ruwa ruwa ne m.A wannan lokacin, ya kamata a motsa ruwan tanki tare da iska mai matsa lamba don magance irin waɗannan matsalolin.

2. Zazzabi ko ƙaddamar da maganin rini ba daidai ba ne. An gabatar da tsarin haɗuwa kuma an ƙara lokutan haɗuwa.

3, saurin rini yana da sauri sosai.Ƙasa na workpiece na farko a cikin maganin rini kuma a ƙarshe ya bar maganin rini, don haka kasan shine mafi sauƙi don fenti mai zurfi.Maganin shine daidaita launi na diluted, dace tsawo na lokacin rini.

4, rashin wutar lantarki mara kyau.Mayu na iya lalacewa ta hanyar masu ratayewa, kula da rataye na iya guje wa irin waɗannan matsalolin.

5, rini yana da bakin ciki sosai, ana iya ƙarawa don inganta taro.

6. The zafin jiki na rini bayani ne ma low.The rini bayani za a iya mai tsanani zuwa kasa 60 ℃.

7, rini na narkar da ba daidai ba, ko kuma akwai rini maras narkewa yana iyo, mai sauƙin samar da bambancin launi.Maganin shine inganta narkewar rini.

Dalilai da maganin gazawar rini

1. Rashin isasshen kauri na fim din anodic oxidation. Maganin shine don duba ko tsarin tsarin iskar oxygen na anodic ya daidaita, don ganin ko yawan zafin jiki, ƙarfin lantarki, ƙaddamarwa da sauran abubuwan sun kasance barga, idan na al'ada, don Allah daidaita ƙayyadaddun ƙayyadaddun daidaitattun, idan babu babu. rashin daidaituwa, za a iya tsawaita lokacin iskar oxygen da kyau, don tabbatar da cewa kaurin fim ɗin ya kai daidai.

2. Ƙimar pH na maganin dye ya yi yawa, a wannan lokacin, ana iya amfani da glacial acetic acid don daidaita darajar pH zuwa daidaitattun darajar.

3. Bayan hadawan abu da iskar shaka, da workpiece da aka sanya a cikin tanki na dogon lokaci. Mai ba da shawara ga rini lokaci, idan wannan halin da ake ciki ya faru, da workpiece za a iya sanya a cikin anodic hadawan abu da iskar shaka tank ko nitric acid neutralization tank dace kunnawa jiyya sa'an nan kuma rina, da sakamako. zai yi kyau sosai.

4. Zaɓin rini mara kyau.Ya kamata a zaɓi rini mai kyau.

5, rini ya lalace ko m, a wannan lokacin ana buƙatar maye gurbin rini.

6, yawan zafin jiki na oxyidation yana da ƙananan ƙananan, yana haifar da nauyin fim na fata. Za'a iya ƙara yawan zafin jiki na oxidation daidai.

7, rashin amfani da wutar lantarki mara kyau. Yiwuwar rashin daidaituwa mara kyau kamar yadda aka nuna ta hanyar rashin daidaituwa na sandar jan ƙarfe na anode ko farantin gubar cathode. Kula da hankali don tsaftace sandar jan ƙarfe na anode da farantin katako na cathode don tabbatar da kyakkyawan aiki.

Dalilai da magance fararen tabo da fallasa

1, ruwa baya tsafta, a karfafa ruwa.

2. Ruwan da ake amfani da shi don wankewa yana da datti kuma yana da sauƙi don gurɓata fim din.A wannan lokacin, ya kamata a canza ruwa don tabbatar da ingancin wankewa.

3. Fim ɗin oxide yana ƙazantar da hayaki da ƙura a cikin iska, acid da alkali hazo.Ingantacciyar wankewa, rini na lokaci, canja wuri na lokaci zai iya rage wannan alamar.

4, fim din oxide yana gurbata ta hanyar mai da gumi da gumi. Dole ne a karfafa kariya, kada ku taɓa bayyanar da kayan aiki da hannu.

5. Akwai datti da ba za a iya narkewa a cikin maganin rini ba, wanda mai ya gurbata shi kuma yana lalata rini na yau da kullun.A wannan lokacin, ya kamata a tace ko maye gurbin maganin rini, kuma a tsaftace ruwan tanki akai-akai.

6, da workpiece rata, zurfin rami saura acid kwarara daga, don ƙarfafa wanke irin wannan workpiece.

7, A rini bayani ne gurɓata da kuma sa pitting lalata da rina workpiece.A wannan lokacin, dole ne a canza launi.

Dalilai da maganin rashin daidaituwa

1. Ƙimar pH na maganin rini yana da ƙananan, kuma za'a iya daidaita ruwan ammonia mai tsarma zuwa daidaitattun darajar.

2, tsaftacewa ba shi da tsabta.Ya kamata a wanke ruwa sosai.

3, Rini ba a narkar da shi gaba ɗaya, ƙarfafa narkewa don cikawa.

4, zafin rini yayi yawa, rage zafin.

5, oxidation film pore ne karami, dalilin shi ne cewa hadawan abu da iskar shaka zafin jiki ne ma low, hana fata fim da aka narkar da sulfuric acid, za a iya daidai daidaita zuwa high oxidation zafin jiki don kauce wa wannan matsala.

6, rini da canza launin da sauri, kuma lokacin rini ya yi gajere, za a iya gyara rini mai laushi, rage yawan rini, dacewa don tsawaita lokacin rini.

7, zafin ramin rufewa yayi ƙasa da ƙasa, maganin dumama.

8. Idan ƙimar pH na maganin rufewar rami ya yi ƙasa sosai, daidaita shi zuwa daidaitattun ƙimar tare da tsarma ruwan ammonia.

9. The fentin surface ne mai sauki eraase.Babban dalilin shi ne m fim, kullum hadawan abu da iskar shaka zafin jiki ne ma high.Ya kamata a biya hankali ga sarrafa hadawan abu da iskar shaka zafin jiki a cikin daidaitattun kewayon.

A kan lahani na canza launin gashi na gashi, ɗauki matakan da suka dace, ingancin kayan canza launin aluminum dole ne su sami damar daidaitawa, don saduwa da bukatun abokin ciniki.

Lokacin aikawa: Afrilu-02-2021