Dukanmu mun san cewa a cikin samar da bayanan martaba na aluminum, riba = tallace-tallace na rage farashin samarwa. Jimlar farashin bayanin martabar aluminum ya kasu kashi ƙayyadadden farashi da farashi mai ma'ana. Kafaffen farashin irin su hayan tsire-tsire, raguwar kayan aiki, da dai sauransu Yana daidaitawa.Kuma m farashin yana da yawa sassauci.

A cikin yanayin farashin tallace-tallace na bayanin martaba na aluminum, mafi girman farashin bayanin martabar aluminum, ƙananan riba. A halin yanzu, a ƙarƙashin yanayi mai tsanani na tashin farashin albarkatun kasa, karuwar albashin ma'aikata, godiyar RMB, tashin farashin makamashi. karuwar nauyin haraji da sauransu, gasar a cikin masana'antar guda ɗaya ta shiga cikin "farin zafi" a yau. Lokaci ya yi don kula da farashi mai kyau.

Gudanar da farashi shine mabuɗin da kamfani ke gudanarwa da kuma ainihin. Kawai ta hanyar samun hanyar haɗi mara ƙarfi, ma'adinai na ciki, na iya amfani da duk hanyoyi da hanyar da za a rage farashin, cikakken shiga, farawa daga cikakkun bayanai, farawa daga rage sharar gida, aluminum. da kyau ga aiwatar da sarrafa farashi, zai iya faɗaɗa sararin rayuwar kasuwancin yadda ya kamata, inganta matsayin gudanarwar masana'antu, sanya kasuwancin ci gaba mai ɗorewa, kuma yana cikin matsayi mara kyau.

Ƙididdigar farashin bayanin martabar aluminum yana dogara ne akan sarkar ƙima a matsayin jagorar, ana rarraba kulawar farashi zuwa ƙirar ƙira, farashin sayayya, farashin masana'anta, farashin tallace-tallace da farashin sabis.Saboda sarrafa farashin ya ƙunshi yanki mai faɗi, abun ciki yana da yawa. Zan yi magana. game da yadda za a inganta ƙimar ƙãre kayayyakin daga ra'ayi na masana'antu domin rage samar da farashin.

Ta hanyar nazarin bayanai da aiki, an tabbatar da cewa inganta yawan amfanin gona na aluminum gami da bayanan martaba yana daya daga cikin hanyoyin kai tsaye da tasiri don rage yawan farashin samarwa.Daukar taron bitar extrusion a matsayin misali, za a rage farashin samar da kayayyakin aluminium da yuan 25-30 a kan kowace ton idan aka karu da kashi daya cikin dari, kuma raguwar bangaren shi ne ribar da kamfanin ke samu.Don inganta fitar da kayayyaki. yawan amfanin ƙasa, aikin samar da shi shine rage sharar da ake fitarwa.

Yadda za a inganta yawan amfanin gona na bayanan martaba na aluminum don rage sharar gida na aluminum, inganta yawan aiki, da rage farashin samar da bayanan martaba na aluminum, mun taƙaita sharar da aka fitar:

Sharar gida na aluminum extruded profiles za a iya raba kashi biyu Categories: geometric sharar gida da fasaha sharar gida.Geometric sharar gida ne wani m sharar gida samfurin na aluminum gami profiles a lokacin extrusion.Such kamar extrusion na saura abu, mikewa kayayyakin a duka iyakar chuck, Girman kayan bai isa ba tsawon tsayin kayan da aka watsar, yanke samfurin da ake bukata, shunt hade mutu a cikin ɗakin shunt na ragowar aluminum block, ingots da samfurori sun yanke girman girman kayan da aka yi da katako. amfani da guntuwar aluminium da ingots na aluminium da aka cinye yayin gwajin ƙura.

Sharar gida na fasaha shine sharar da aka samar ta hanyar fasaha mara kyau, matsalolin kayan aiki da kuma aiki mara kyau na ma'aikata a cikin tsarin samar da bayanin martaba na aluminum.Bambanci daga samfurori na geometrical, zai iya shawo kan yadda ya kamata da kuma kawar da samar da samfurori na fasaha ta hanyar inganta fasaha da ƙarfafa gudanarwa. .Za a iya raba sharar fasaha zuwa:

Kayayyakin sharar nama: ƙonawa, ƙaƙƙarfan zoben hatsi, ƙananan hatsi, raguwar wutsiya, haɗaɗɗen slag, da sauransu.

Kaddarorin injina marasa cancanta: ƙarfi, taurin ya yi ƙasa da ƙasa, ba su cika ka'idodin ƙasa ba;ko filastik ya yi ƙasa da ƙasa, rashin isasshen laushi bai dace da buƙatun fasaha ba.

Samfuran sharar gida: yadudduka, kumfa, fasa extrusion, kwasfa orange, clauses nama, baƙar fata, layin walda mai tsayi, layin walda mai jujjuyawa, karce, latsa ƙarfe, da sauransu.

Kayayyakin sharar ma'auni na geometric: igiyar ruwa, karkatarwa, lanƙwasa, sharewar jirgin sama, girman rashin haƙuri, da sauransu.

Adadin samfuran da aka gama rabon jerin ayyuka na samfuran da aka gama da cikakken yawan amfanin ƙasa.

Tsarin ƙãre aluminum rabo gabaɗaya yana nufin babban tsari, yawanci dangane da bitar a matsayin naúrar don lissafi.Casting tsari (casting bitar), extrusion tsari (extrusion tsari), hadawan abu da iskar shaka canza launi (oxidation bitar), foda spraying tsari (spraying bitar) .An bayyana shi a matsayin rabon ƙwararrun kayan aikin bitar zuwa shigar da albarkatun ƙasa (ko samfuran da aka kammala) a cikin bitar.

Adadin samfuran da aka gama yana da alaƙa da ingancin kayan aiki, ingancin ingot, tsarin samfur, yawan canjin iri da ƙayyadaddun bayanai, babban digiri na fasaha, matakin sarrafa kamfani da ingancin masu aiki da sauran dalilai.

Makullin don inganta haɓakar bayanan bayanan allo na aluminum shine don ragewa da kawar da abubuwan sharar gida.Sharar gida na geometric ba shi yiwuwa, amma ana iya rage shi. .Saboda haka, ingantaccen iko da haɓaka yawan amfanin ƙasa na samfuran extruded za a iya karɓa.

Rage sharar lissafi shine muhimmin abin da ake buƙata don haɓaka yawan amfanin da aka gama

Matakan rage sharar geometric

Madaidaicin zaɓi na tsayin ingot shine babban ma'auni don rage yawan sharar gida.Ba a ƙididdige tsawon lokacin da aka yi amfani da shi ba bayan extrusion, amma an ƙididdige shi bayan extrusion.

Yanzu yawancin kamfanoni suna amfani da dogon sanda mai zafi mai ƙarfi aluminum sanda dumama makera, idan aka kwatanta da gajeren sanda dumama makera, rage asarar aluminum kwakwalwan kwamfuta, saboda canji na mold bango kauri, da simintin gyaran kafa tsawon iko ne mafi m da kuma m, ƙwarai inganta. da yawan amfanin ƙasa.Amma da yawa Enterprises a cikin yin amfani da dogon sanda zafi karfi makera, watsi da lissafin da simintin tsawon, da kuma kai tsaye mika aikin ga afareta don control.Kuma mai aiki ne sau da yawa bisa kwarewa a karkashin na farko mashaya, lura da tsayin kayan aiki, idan bambanci yana da girma, ci gaba da daidaitawa, yawanci yana buƙatar kusan sanduna 3 don samun daidaitaccen tsayin daka.

Hanyar da ta dace ita ce tsayin ingot an ƙididdige shi ta hanyar sashin kula da tsari a lokacin farkon samar da mold.Lokacin da aka samar da ƙirar a kan na'ura sau da yawa, tsawon sandar da aka rubuta a kan katin ƙira ya ƙaru da kusan 5-10mm, kuma ana lura da tsawon kayan lokacin da aka samar da kayan aiki. Gyaran da kyau idan akwai. bambance-bambance.Saboda haka sanda na biyu ya kasance daidai sosai.A cewar wasu bayanai, ana iya ƙara yawan amfanin da aka gama da kashi 4 cikin dari ta hanyar amfani da dogon lokaci mai zafi, kuma yana yiwuwa a kara yawan amfanin gona da kashi 2 zuwa 3 a ainihin. samarwa.

Bugu da ƙari, adadin ƙayyadadden tsayi ko tsayin samfurin, don tabbatar da aikin extrusion mai santsi a ƙarƙashin yanayin extrusion.Lokacin da tsayin gadon sanyi ya isa tsayi, ƙara tsawon tsayin ƙayyadaddun ƙayyadaddun ko tsawon samfurori. kamar yadda zai yiwu, wato, za a iya zaɓar mafi tsayi ingot.Haka kuma hanya ce mai mahimmanci don rage yawan adadin sharar lissafi da kuma ƙara yawan amfanin da aka gama.

Matakan don inganta ƙimar ƙãre kayayyakin daga matakin fasaha

Yana da mahimmancin ma'auni na fasaha don inganta ƙimar ƙãre samfurori don inganta matakin ƙirar ƙira da ƙira da kuma rage Times of mold test. Gabaɗaya ba wannan gwajin ƙirar ƙirar ƙira 1-3 ingots ba, don haka yawan amfanin ƙasa ya rage 0.5-1. %, saboda ƙira na mold, ƙananan masana'antu matakin, wasu samfurori don gyara mold, mold sau 3-4 ko ma fiye da sau da yawa don samar da samfurori da aka gama, rage yawan amfanin ƙasa na 2-5%, wanda ba zai haifar da tattalin arziki kawai ba. hasara, amma kuma saboda maimaita gwajin mold, zai tsawanta sake zagayowar samarwa.

Tsarin gwajin sifili na zamani na zamani, wato, bayan an ƙera ƙirar, babu buƙatar gwada ƙirar, za ku iya kai tsaye kan injin don samar da samfuran ƙwararrun. computer.Haka kuma ana iya gwada shi ta hanyar simulation na kwamfuta. Ana kammala aikin sarrafa cavity a cikin cibiyar sarrafa kayan aiki ta atomatik, sarrafa dukkan mold ɗin yana da inganci sosai, don haka ingancin ƙirar yana da girma sosai. 90% zai iya ƙara yawan amfanin da aka gama da 2-6%.

Da kyau ƙara haɓakar extrusion na aluminum don inganta yawan amfanin ƙasa

Kowane masana'anta na aluminum yana da jerin injuna, kowane masana'anta bisa ga ƙimar extrusion na samfurin, tsayin gadon sanyi, sashin waje na samfurin, tsayin diamita na silinda extrusion, don tantance samfurin akan injin daidai. Production.Practice ya tabbatar da cewa ƙayyadaddun ƙayyadaddun samfuran, sanya a cikin samar da injin tonnage daban-daban, saboda ƙayyadaddun ƙayyadaddun extrusion daban-daban, tsarin aikin samfurin da ingancin samarwa yana da tasiri mai girma, yawan amfanin sa kuma zai haifar da bambance-bambance. ton na'ura na extrusion ya fi girma, ƙimar extrusion ya fi girma, ƙimar samfurin da aka gama ya fi girma, kuma farashin extrusion yana kusa.

Inganta ingancin ingot shine jigo na inganta yawan amfanin ƙasa

Ingots sune albarkatun kasa na samar da extrusion.Ingots da uniform tsarin, lafiya hatsi, babu slag, pores, segregation, fasa da sauran lahani, wanda ba zai iya kawai rage extrusion matsa lamba, inganta extrusion gudun, da kuma inganta ciki ingancin kayayyakin.And iya rage samfurin surface kumfa. pores, scratches, fatattaka, pitting da sauran lahani.Ƙananan slag hada da za a iya saki ta hanyar tsaga na mold aiki bel, amma shi zai haifar da pear alamomi a kan profile surface, haifar da wani tsawon sharar gida.The girma slag hada da zai. a makale a cikin tsagewar bel ɗin aiki kuma ba za a iya kawar da shi ba, wanda zai haifar da toshewar ƙirƙira ko samfuran fashe kuma ya maye gurbin mold, wanda zai yi tasiri sosai ga yawan amfanin ƙasa.Yi amfani da pads masu dacewa lokacin shimfiɗawa da daidaitawa don rage yanke tsawon kai da wutsiya. abu.

Profile a mike tsaye, yawancin masana'antu ba sa tsara matashin da ya dace, musamman ma wasu manyan bayanan martaba da rataye da rataye. sawing da ƙãre samfurin.Wannan ya haifar da raguwa a cikin adadin ƙãre kayayyakin.

Za a iya yin matashin da katako ko tubalan aluminum.Zane yana rage girman matashin matashin kai kuma yana ƙara haɓakawa.Don tsayin bango da rufaffiyar sashin bayanin martaba, daidaitawa a cikin rufaffiyar rufaffiyar cikin kushin amma kuma sanya firam ɗin tallafi a cikin ɓangaren bangon.Ta haka, nakasar a ciki. an rage tsawon shugabanci. Dole ne a tsara kayan aiki, sarrafawa da jagoranci ta hanyar ma'aikata na musamman.

A lokaci guda, don hana al'amarin cewa ma'aikata ba sa son yin amfani da matashin saboda matsala, dole ne mu kafa tsarin lada da azabtarwa wanda adadin samfurin da aka gama yana da alaƙa da albashi.

Ƙarfafa gudanarwar mutuwar extrusion da rikodin samar da asali na bayanin martaba na aluminum.

Katin ƙira da rikodin samarwa na asali suna da mahimmanci.Dole ne katin ƙira ya iya nuna ainihin yanayin nitriding na mold, yanayin kulawa da yanayin kayan aiki.Dole ne rikodin asali ya iya nuna da gaske cewa nauyin tallafi, tsayin daka da yawa suna ba da ingantaccen tushe don samarwa na gaba.

Yanzu kamfanoni da yawa ma sun fahimci sarrafa bayanan kwamfuta, amma har yanzu akwai sauran rina a kaba a ainihin amfani.

Rage sharar geometric ta amfani da latsa mara amfani bayan extrusion

An kafa kafaffen kushin a kan sandar extrusion ba tare da ragowar extrusion ba, kuma an canza su biyu zuwa wani matsayi.Lokacin da silinda extrusion ba ta ja da baya ba, matsi na matsa lamba yana da sauƙi don rabu da ingot. Na gaba ingot an tura kai tsaye. A cikin harsashi na extrusion. An fitar da shi tare da ragowar abubuwan da suka gabata na baya, don haka guje wa buƙatar shear kowane ingot sau ɗaya. Dangane da ƙayyadaddun ƙayyadaddun buƙatun da adadin oda don ƙayyade adadin matsi na simintin gyare-gyare. Yawancin lokaci 40-50 an yanke a wani wuri. lokaci.

Inganta tsarin extrusion na bayanan martaba na aluminum don rage sharar fasaha

Akwai da yawa al'amurran da suka shafi extrusion tsari na fasaha sharar gida, wanda ya rufe dukan extrusion samar da tsari.Mainly hada da: ingot ingancin, tsari zafin jiki, extrusion gudun, extrusion kayan aikin, mutu, canja wurin loading da saukewa, tsufa magani, da dai sauransu. ci gaban ci-gaba, fasahar samar da kimiyya, amma kuma daidaitaccen aiwatar da tsarin aiki, inganta ƙwarewar ma'aikata da fahimtar alhakin.

Kamar yadda zai yiwu don rage nau'in nau'in samarwa a kowace motsi, yana da kyau a shirya nau'in nau'in 3-5 kawai a kowace motsi, don inganta samar da nau'in nau'i na nau'in nau'in nau'in nau'in nau'i. dauke, da ƙananan yawan amfanin ƙasa.

Tasirin mold akan yawan amfanin ƙasa shine yafi a cikin bangarori biyu: sabon gwajin ƙira da amfani da ƙirar ƙira

Yawancin lokutan da aka gwada samfurin, yawancin aluminum da aka cire, kuma ƙananan yawan amfanin ƙasa. Don haka dole ne mu inganta ƙirar ƙira da samar da samfurin.

Ya kamata a kiyaye samar da mold a hankali, m nitriding, tabbatar da lokaci. Tabbatar da kowane lokaci a kan na'ura mai cancantar ƙimar yana da girma.Good gyare-gyare da kuma babban durability.If kowane motsi saboda gyaran gyare-gyaren da bai dace ba, yana haifar da nau'in 3-4 akan gazawar samar da injin. , za a rage adadin samfuran da aka gama da aƙalla kashi ɗaya cikin ɗari.

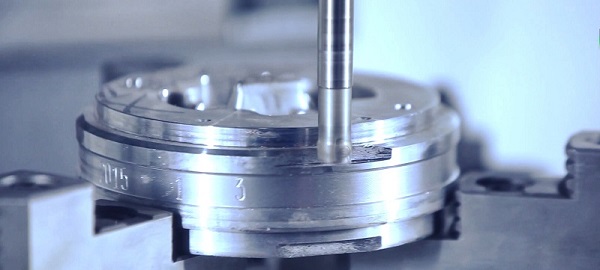

Aluminum extrusion kayan aikin sun hada da: extrusion Silinda, extrusion sanda, extrusion kushin, mutu kushin, da dai sauransuMainly don tabbatar da cewa extrusion Silinda, sanda, mold uku concentric.Na biyu, m kiyaye extrusion Silinda, daidai dumama, don tabbatar da cewa karshen saman Silinda yana da santsi.Kawar da kowane nau'in silinda extrusion kuma ya mutu tare da mummunan al'amari. Tsaftace ragowar aluminum a cikin bangon ciki na silinda na extrusion akai-akai, duba ko bangon rami na ciki ya lalace, yi amfani da kushin mutu daidai, kuma inganta ƙarfin tallafi na mutu.

Extrusion zafin jiki, extrusion gudun da kuma sanyaya uku, a kan samfurin tsarin, inji Properties, surface ingancin yana da babban tasiri, kuma zai shafi yawan amfanin ƙasa. gudun extrusion yana da sauri, yanayin sanyi yana da ƙasa, zai sa tsawon samfurin bayan karuwa ya karu, girman girma zai iya zama har zuwa 0.5% - 1%, kuma yana rinjayar madaidaicin madaidaicin bayanin martaba, don haka tsarin barga zai iya. inganta yawan amfanin ƙasa.

Inganta m extrusion tsari don kauce wa fasaha sharar gida.Extruding na gaba tsari na sufuri, yafi kula da bayanin martaba na karce.

Daya mutu porous extrusion iya inganta yawan amfanin ƙasa na ƙãre kayayyakin.

Ga wasu samfurori masu dacewa da haɓakar iska mai yawa, har zuwa yiwu ta amfani da extrusion mai laushi, ba wai kawai zai iya rage yawan ƙwayar extrusion ba, ragewa da matsa lamba, amma kuma zai iya inganta yawan amfanin ƙasa. za a iya ƙara extrusion ramuka biyu da 3% ~ 4% fiye da na extrusion rami guda.

Extrusion gudun ne mai muhimmanci tsari siga a cikin extrusion tsari, wanda shi ne alaka da ingancin kayayyakin da samar efficiency.Extrusion gudun ba son Master tsarin zafin jiki, wani irin gami wani zafi magani tsari iya m zabi wani zazzabi, da kuma gudun extrusion ne mai matukar empirical tsari siga.Samfurin guda ɗaya yana shafar canje-canjen zafin jiki a cikin tsarin extrusion, kuma saurin extrusion ya bambanta kafin da bayan extrusion.Don sarrafa saurin extrusion daidai, yakamata ya zama:

Da fasaha da sassauƙa fahimtar kewayon extrusion gudun daban-daban gami, daban-daban sassa (ciki har da bango kauri), da kuma kula da tasiri na extrusion gudun a kan aluminum profiles, kamar surface quality, gyare-gyaren digiri, da dai sauransu.

Sanin da ikon extrusion kayan aiki don sarrafa extrusion gudun.Wasu extruders da m extrusion iko da PLC iko, wasu da kawai PLC iko, da kuma wasu ba su da.Lokacin da aka ba extrusion gudun, wasu extruders iya fara danna gudun extrusion. tare da raguwa a hankali na billet a cikin silinda extrusion, matsa lamba yana raguwa, saurin fitowar samfurin zai yi sauri da sauri, wani lokacin yin samfurin bayan fashewa.Saboda haka, ya zama dole don daidaita saurin extrusion.Ta hanyar kawai fahimtar yanayin kayan aiki za a iya daidaita saurin extrusion daidai da sarrafawa.

Fahimtar tasirin molds daban-daban a saman sprusion Speew.Gaukar Saurin Ruwa na Ruwa (Sassan Haske na Samfurin, saboda ƙirar ƙira da matakin masana'anta ya bambanta, saurin extrusion ya bambanta.Musamman, sashin yana da bambancin kauri na bango, ko bayanin martaba mai zurfi tare da buɗewa, wanda ke da alaƙa mai girma tare da mold.Kawai wani gudun extrusion da aka tsara ta mold shine mafi kyau.Gudun yana da sauri sosai ko kuma a hankali, kuma yana da sauƙi don samar da juyawa da buɗewa da rufewa.

Rage samar da sharar gida ta hanyar ƙarfafa binciken farko da binciken tsari

Girman waje na samfuran sharar aluminum, kamar kauri na bango daga juriya, karkatarwa, izinin jirgin sama, buɗewa ko rufewa, da sauransu, galibi ya dogara da sandar farko bayan gwajin mold ta hannun mai watsa shiri a cikin dubawar fitarwa da ingantacciyar insfekta. a cikin binciken da aka yi amfani da shi don hana samar da irin waɗannan kayan sharar gida.Ya kamata a sarrafa juriya na kauri na bango daga mummunan haƙuri, saboda tare da ci gaba da samar da samfurori, kauri na bangon samfurori zai zama mai kauri a hankali saboda raguwa a hankali. na mold.Don manyan bayanan bangon bango, lokacin zana da kuma daidaitawa don duba zane a hankali, sarrafa ma'auni mai ma'ana.

Surface sharar gida kamar scratches, orange kwasfa, nama, baki spots, kumfa, sau da yawa ba duk na tushen kayayyakin bayyana.It wajibi ne don duba juna ta hanyar rundunar afareta, da ingancin inspector da sawing aiwatar da mikewa ƙãre samfurin, kuma tare da haɗin gwiwar kula da kawar da abubuwan sharar gida a saman.

Idan ingantattun inspector bai sami scratches a kan fitarwa tebur, kuma ya sami scratches a kan ƙãre kayayyakin a lokacin da sawing, shi wajibi ne don duba daga tuba tsari na sanyi gado don ganin ko wasu sassa na kai bel, digger da sauransu. suna da wuya kuma suna shahara, suna haifar da karce.

Gudanar da inganci shine gudanar da dukkan ma'aikata da dukan tsari.Kowane tsari dole ne ya kasance yana da inganci mai kyau, don haka za'a iya haɗawa da dubawar kai, dubawar juna da dubawa na musamman, don kawar da sharar fasaha a cikin toho.Ikon wucin gadi da inganta yawan amfanin ƙasa.

Ta hanyar matakan da ke sama na iya rage sharar lissafi na geometric, ana iya ganin cewa rage yawan sharar gida shine muhimmin matakan sarrafa fasaha ga kamfanoni, wanda ke da mahimmanci ga fa'idodin tattalin arziki.

Don inganta yawan amfanin ƙasa na billet extrusion na aluminum shine don kammalawa da kuma aikin aiki mai mahimmanci na samar da extrusion, ba kawai abubuwan fasaha ya kamata su kasance a wurin ba, amma har ma abubuwan gudanarwa ya kamata su kasance a wurin. kamfanoni don inganta yawan amfanin ƙasa, yawan amfanin ƙasa zai kasance ci gaba da aiwatarwa, haɓaka yawan amfanin ƙasa da haɓaka ingancin samfur, fitarwa yana da alaƙa da alaƙa. Fasaha ce ta kasuwanci da matakin gudanarwa na cikakkiyar tsari.

Inganta yawan amfanin ƙasa na aluminum masu launin oxidized

Abubuwan da ake samu na oxidation shine yawan samarwa guda ɗaya, wato, yawan amfanin ƙasa ɗaya ba tare da sake yin aiki ba.Bisa ga aikin samarwa, farashin bayanan da aka sake yin aiki shine sau 3 na bayanan da ba a sake yin aiki ba, kuma ba za a iya tabbatar da ingancin bayanan martaba ba.Hakika, ingancin samfuran oxidized yana farawa daga aikin simintin gyare-gyare.Saboda ƙuntatawar sararin samaniya, mai zuwa shine taƙaitaccen magana game da wasu cikakkun bayanai waɗanda ya kamata a kula da su a cikin tsarin samar da iskar oxygen.

Yakamata a ƙara ƙulla dunƙule tsakanin sandar rataye da katako mai ɗaukar nauyi.Kafin ɗaure kayan, ya kamata mu fara bincika ko sandar rataye tana kwance.Idan yana da ɗan sako-sako, ya kamata a ƙara a cikin lokaci. Wani lalata, sandar rataye zai zama karami, yana buƙatar maye gurbin lokaci, saboda wurin da yake da shi yana da ƙananan, sauƙi don haifar da zafi, a lokaci guda don ɗaure, hana bayanin martaba yana fadowa cikin ramin da sandar sanda ta haifar, gajeriyar lalacewar wutar lantarki.

A lokaci guda faɗuwa cikin profile na tanki ya kamata a tsaftace cikin lokaci, kamar tankin alkali a cikin bayanin martaba, ba da daɗewa ba zai lalata, gwajin ya tabbatar da cewa shan alkali yana daidai da wanke alkali na 50-100. Tushen bayanin martaba na amfani da alkali.Faɗawa cikin tanki mai canza launi ko tanki mai rufewa, saboda lalata, tankin zai tara adadi mai yawa na ions na aluminum, yana shafar rayuwar sabis na ruwa na tanki.

Daure abu da aluminum waya tare da iri biyu bayani dalla-dalla yana da kyau, aniseed zabi m aluminum waya, matsakaici da kuma kananan abu da ake amfani da a lafiya aluminum waya, za a iya amfani da 2mm da 3mm, ko 2.2mm da 3.2mm iri biyu bayani dalla-dalla, aluminum. Waya annealing taurin yana ɗaukar 1/2 ~ 3/4 yana da kyau. A halin yanzu, yawancin kamfanoni sun canza zuwa jig.

Kafin ratayewa a cikin tanki na oxidation don ƙarfafa kowane bayanin martaba; Kayan aikin sake yin aiki a gaban iskar shaka na kayan, don amfani da pliers don doke ƙarshen bayanin martaba don yin motsi a gaban kayan, don lambar sadarwa ba tare da fim ba, don tabbatar da kyakkyawan aiki. .

Nau'in kayan da ke rataye a cikin tanki mai iskar shaka da wurin zama na tanki mai canza launi ya kamata a kula da hannun dama, in ba haka ba mai saurin kamuwa da bambancin launin Yin da Yang.

Bayan ƙarshen oxidation ikon da aka dakatar a cikin lokaci, zauna a cikin hadawan abu da iskar shaka tank for 'yan mintoci kaɗan zai shafi sealing rami, kuma zai sa gudun canza launi;Ɗayan ƙarshen maganin rage acid ɗin ya yi duhu saboda fadada pore na fim ɗin oxide, kuma bambancin launi a ƙarshen duka yana da sauƙin bayyana.

Ƙimar pH na tankunan wanke ruwa guda huɗu kafin da bayan tankin canza launin ya kamata a kiyaye su da ƙarfi.Ana sarrafa ƙimar pH na tankunan wanka guda huɗu na yau da kullun kamar haka:

Darajar pH na wanka na farko na ruwa bayan hadawan abu da iskar shaka: 0.8 ~ 1.5

Darajar pH na wanka na ruwa na biyu bayan hadawan abu da iskar shaka: 2.5 ~ 3.5

Darajar pH na wanka na farko na ruwa bayan canza launi: 1.5 ~ 2.5

Ƙimar pH na tankin wanka na biyu bayan canza launi: 3.5 ~ 5.0

A karkashin yanayi na al'ada, ana buɗe wani adadin ruwa mai ambaliya yayin samarwa, kuma ana rufe bawul ɗin shigarwa cikin lokacin da aka dakatar da samarwa.Kada ya zube ko ƙara ruwa a cikin dukan tanki.Idan ruwan ya tsaya a cikin tankin wanka na farko bayan oxidation na 'yan mintuna kaɗan, za a ƙara saurin canza launin, kuma idan ruwan ya tsaya a cikin tankin wanka na biyu, za a rage launin launi.

Don samar da kayan aikin ƙarfe mai launin haske mai launin haske, ana amfani da hanyar yin launi gabaɗaya da farko, sa'an nan kuma komawa zuwa farantin launi na yau da kullun.Saboda bambancin launi na kwaikwayi karfen canza launi na lokaci yana da ƙananan (kawai 2 ~ 3 seconds) , kuma yin amfani da ka'idar fadewa na iya samun 10 ~ 15 seconds na lokacin sarrafa launi, kuma faɗuwar haɗin kai shima yana da tasiri ga launi iri ɗaya, don faɗuwar karfe da launuka masu kama da launi suna nuna launin kore, kuma canza launin lokaci ɗaya yana kula da su. yi ja.

Nau'in kayan da aka rataye daga tanki mai canza launi da tankin wanka na farko bayan canza launin bayan rataye kada ku daina komai lokaci yayi tsayi da yawa, in ba haka ba bayanin martaba zai bayyana kintinkiri, launi mara daidaituwa da ƙarshen magudanar ruwa na farin sabon abu, ya kamata ya zama dan kadan akan launi na Na gaba wanke a cikin lokaci, daidai launi ya kamata ya kasance a cikin wanka na biyu bayan. Gabaɗaya magana, don kayan aikin ƙarfe na kwaikwayo, kamar bambancin samfuri launi ja, yana nuna cewa lokacin canza launi bai isa ya dace da launi ba; Idan launin rawaya ne. , An yi launin launi, bisa ga zurfin launi, za ku iya zaɓar komawa baya a cikin tanki mai launi ko a cikin tankin wanka na farko bayan canza launi.

Ƙara hanyar magunguna a cikin tanki mai canza launi: sulfate mai ban mamaki da nickel sulfate dole ne a narkar da su a cikin tanki, kuma dole ne a narkar da kayan canza launi a cikin ruwa mai tsabta (ruwan mai tsabta yana soluble).Dole ne a lura cewa za'a iya zubar da ƙaƙƙarfan ƙari bayan an narkar da shi gaba ɗaya, kuma ana iya zuba sulfuric acid mai mahimmanci a cikin tanki mai canza launi.

Dole ne a tabbatar da yanayin zafin jiki, lokaci da ingancin ruwa na wanke ruwan zafi kafin electrophoresis.Idan saura SO42- a cikin ramin fim din oxide ba a wanke ba, yellowing da opacity na fim ɗin fenti suna iya faruwa bayan electrophoresis da yin burodi. lokaci shine minti 5-10.

Lokacin aikawa: Maris 26-2021